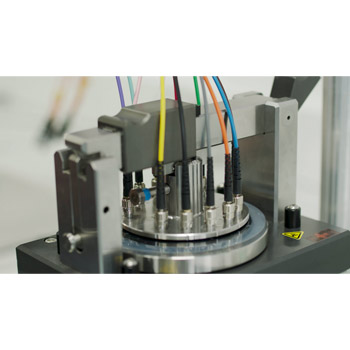

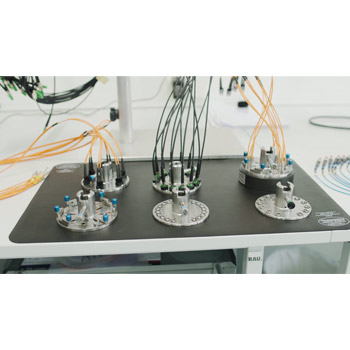

A large selection of fiber optic connectors is being assembled to customer demands.

We are specialized in:

Consulting for the selection of fiber optic connectors and cables, tailored to the field of application.

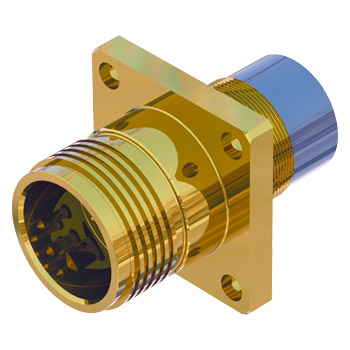

- Fiber optic solutions for rough environments (mil., offshore, industry, broadcast…)

- System cable assemblies

- Expanded beam connectors

- Fiber optic training adapted to customer demands

The need for constantly increasing bandwidth for data transmissions is not limited to local inhouse data networks, data centers or telecommunication applications, but also in outdoor areas. Nowadays we also find the use of fiber optic technology in the following areas:

- Military communications (mobile networks in field camps or vehicles)

- Marine technology (ship, offshore and subseaapplications)

- Mobile broadcasttechnologies (concerts, festivals, theaters, exhibitions…)

- Miningfiber solutions

- Oil and gastechnologies

- Heavy industryapplications

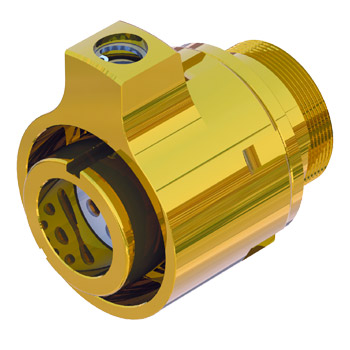

In modern systems the use of fiber optic technologies is indispensable. Products like ELIO, expanded beamsolutions or M29504 ferrules in a wide range of connectors were developed to resist the harshest environments.

Expanded beam connectors are designed to protect the sensitive ferrules against dust, liquids and wrong handling by the operator. Special cleaning and inspection equipment isn’t needed. A main key feature is also the availability of the hermaphroditic design, that offers the advantage to connect a connector to a connector (used on cable drums). The connectors have the same design. Of course, different materials (marine bronze, stainless steel, aluminum hard anodized) and a big variety of back shell versions (90° angle…) are available. Multi-mode and single mode versions up to 24 channels can also be combined.

Furthermore, we offer hybrid versions that have signal and power contacts combined with fiber optic contacts in one connector design.Due to the big variety of products please contact us to find the right solution for your application.